To make power, engines rely on a healthy mix of air and fuel before this is ignited to push pistons down and turn the crank. Both stock and performance engines have this at a defined 14.7:1 ratio to ensure optimal combustion. The only difference being the design restrictions in production engines in terms of how much air comes in, and how much fuel is sprayed in each combustion cycle.

This is limited by factors such as noise and emissions regulations and the fact that car manufacturers want to keep fuel consumption as low as possible. All this limits the usable power in any production powerplant. Pushing more air in is the easiest way to boost engine power.

This is done by installing a performance air intake system that reroutes piping and uses more efficient filters to bring higher air volumes and oxygen-rich air at speeds and angles that ensure all those horses come to good use. Air intakes are often the first upgrade during any engine modification, especially if you’re looking for improved acceleration and a car that’s more fun to drive.

Car Air Intake Basics

Air intakes are a collection of parts tasked with pulling atmospheric air into the intake manifold, where it is mixed with fuel and then ignited. Key components are the air filter that removes external pollutants, intake tubes in designated diameters, mass flow sensors to evaluate air volume and pressure and the throttle body that regulates how much air gets in for combustion. Factory designs are efficient for the rated engine power, but if you want more, there are several aftermarket intakes to choose depending on your needs.

Role of Intake Components

- Air filters – cleanse outside air from dirt, moisture, particles and pollutants that can damage the damage and corrode internal engine parts. Aftermarket filters have more efficient filtering media (cotton gauze) that stock filters, get rid of more contaminants and ensure higher airflow. Most are also reusable, so save on replacement and labour costs.

- Mass Air Flow Meter – measures the volume of air entering the engine and relays readouts to the ECU. This, in turn, makes the necessary fuelling adjustments.

- Tubing – a major benefit of aftermarket air intakes is the wider and straighter tubing. This reduces the airflow limitations common in production systems, leading to higher efficiency and air volumes needed for bigger bangs. Intakes also include heat-shielded materials that keep air cool and richer in oxygen.

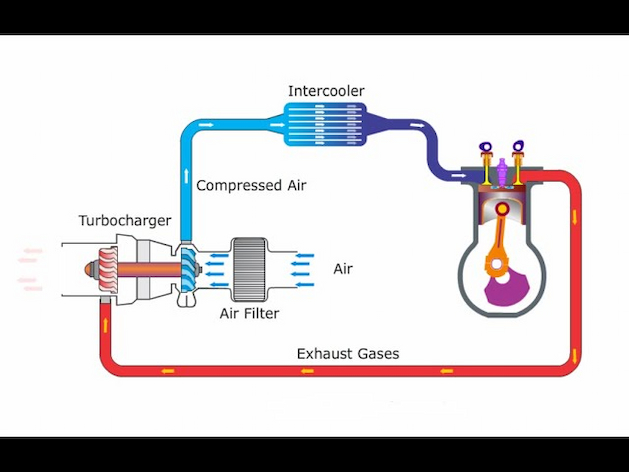

- Turbocharger and intercooler – incoming air is compressed by the turbocharger. This also raises temperatures. To counter higher air temperatures, turbines are paired with intercoolers to cool the compressed air before it’s forced into the combustion chamber. This reduces the likelihood of misfires, detonation and pre-ignition, all of which can lead to engine failure.

- Throttle body – the is the engine part that adjusts airflow depending on the engine load and is either controlled electronically (fly-by-wire) or via mechanical cable when pressing or releasing the acceleration pedal. Defined air volume then passes through the intake manifold where its is distributed evenly among the cylinders.

Common Air Intake Types

Different air intake designs cater to different vehicles and performance needs. This includes:

Cold Air Intakes

These consist of better and bigger filters pushed further to the front of the vehicle, larger piping with heat shielding and in some cases an airbox that stores and supplies higher air volume when needed. Large-diameter cone or dome shaped reusable oiled filters clear more contaminants, scoop air from lower down, and push it through tubing made of reinforced plastics or aluminum at optimal angles and higher speeds. The cooled air from the integrated heat shields is also denser to allow for more efficient combustion. The result is higher horsepower and torque.

Short Ram Intakes

For cars with smaller engine bays, consider the simplicity and low cost of short ram intake systems. These replace stock air boxes housing the filter with shorter and straighter tubes inside the engine bay, paired with larger, often enclosed filters. The layout, while similar to a cold air intake, is shorter in length (thus the name). And it misses out on the complex tubing placed further from hot engine parts like the turbo or manifolds. While these intakes do supply higher air volumes than intakes in unmodded powerplants leading to a louder engine burble and slight power gains, they pale in comparison to cold air intakes for outright horsepower and torque gains due to higher air temperatures.

Why Go Aftermarket? Benefits of Aftermarket Intakes

Intakes set the scene for further modifications. Improved filters reduce potential engine wear, cause less flow restrictions and ensure longevity with fewer maintenance intervals. Buyers can choose between reusable oiled and dry filters, depending on the needs. Power gains though are why to go with an aftermarket intake. Vehicles have significantly faster throttle response, meaning effortless acceleration, and they use less fuel for specified engine loads due to lower stresses. The result is a louder, deeper engine sound.

Pair the parts with equally-capable performance exhaust parts for the best results, and consider an ECU tune to balance the fuelling. Go with short-ram air intakes in the engine if short on space, or go with a full cold air system to enjoy all the benefits.