Insulation testers are devices that require a lot of technicalities to be considered both when purchasing and using them, which is what makes things so complicated. On the market you can find various low-end insulation resistance testers that have features and specifications similar to those of more industrial models, so you may think that your low-end unit is well-suited to the work you need to do. And maybe it is, but chances are it isn’t, and if that’s the case, you could endure injury, lost time, incomplete testing, and recurrent downtime. As is with most pieces of test equipment, insulation resistance testers require you to do some research before deciding which model to invest in. Here’s a bit of help on the matter.

What To Consider

• First what you need to be aware of is the measuring current which will allow you to measure different properties. For example, if you are going to measure the polarization index, you’ll want to look for insulation testers that can hold up well when performing that test since it takes usually about 10 minutes or so. A leakage current test provides you with the amount of contamination in insulation by applying the test voltage to the component of choice, which is called ‘spot reading’ and it normally lasts only around 60 seconds.

• The environment in which you’ll be using the tester the most is going to play a big role in what features and capabilities you’ll want it to have. Will you use it outside or inside? Will it be used in a small shop or in an industrial plant? And will it need to perform just troubleshooting or preventative maintenance too? Things like digital or analog, automated settings and computer capabilities will depend completely on your personal preference.

• Low-voltage protection plays a big part in staying safe when using insulation testers which makes it a must-have feature. Quality insulation testers have what is called a ‘contact detector’ feature which prevents the tester from becoming live when connected at source voltage. This can otherwise become an extremely dangerous situation as any metal that the second probe gets connected to will become similarly energized. This happens due to the low impedance being set by the continuity range so it can allow for a large test current.

• IP (ingress protection) may not be something to protect the user but it is relevant when it comes to protecting the tester. By protection, I mean keeping it running when exposed to dust, grime, and water. The first digit tells you about dust and object protection while the second is all about how waterproof the device is – the greater those numbers are, the better. The IP rating given on most insulation testers is usually 54 which signifies that the device is protected from wires and other objects no bigger than 1.0mm and that it is also protected from water splashes coming from any direction.

• Safety is paramount when working with high voltage devices which is why you should pay attention to the following things and not settle for anything else. The tips of the test leads should be covered with a protective boot showing the least amount of metal possible and they should also be sleeved and shrouded in so they keep your fingers away from the metal. A quality tester will also have recessed connections to prevent accidental contact with metal jacks and have switched probes for safer and more convenient use. Fused leads are also a sign of a high-quality tester.

How-to

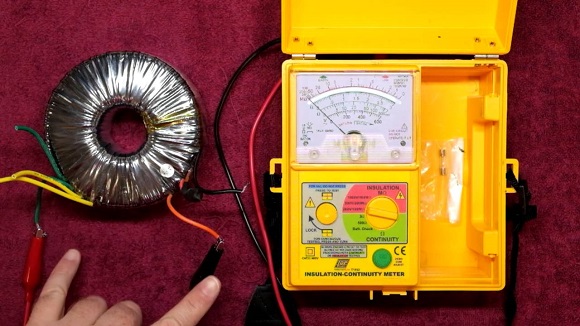

• Setting your tester for the right type of test will require you to know all the information about it which is usually provided in a manual. No matter how experienced you are, it is always helpful to remind yourself about a certain test that you want to perform so you can get the proper results. Most insulation testers will offer the polarization index (PI), dielectric displacement (DD), step voltage (SV), dielectric absorption ratio (DAR) and ramp tests by default, so make sure you know how to carry them out properly.

• Setting the appropriate test voltage is also important in order to provide as much information possible about a certain object without damaging it. While high voltage testing can give you an immense amount of information, you should always follow the supplier’s data on how much voltage you’ll need in order to perform the test safely.

• Something that occurs quite often is surface leakage and to prevent it from happening it’s best that you use the tester’s guard terminal. This will either eliminate reduce the effect of surface leakage. The guard terminal is usually connected to a bare wire wrapped around the surface of the object at test.

• It’s best that you use a tester with a high-measuring range which will alert you whenever your instrument shows all results beyond a certain number of measurement as infinity. If you don’t get a high measuring range instrument, that small issue can easily become a serious one in the future.

• A big part of every insulation tester is its leads, which can become a safety hazard right away if you don’t look after them or store them properly. Although quite basic, it’s important that you always use test leads made to be used with the test voltage at hand and ones that have secure connections on them. If you see any sign of damage or wear, it’s best that you replace them as otherwise, you can end up causing even more damage.